Applicationem

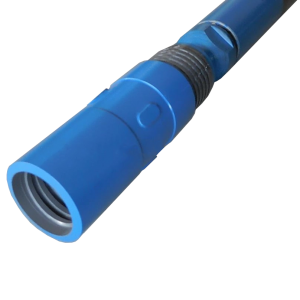

In cylindro pyramis frenum instrumentum late in usu petrolei exercendis et geologicis exercendis est.Tricone frenum habet munus impactionis, opprimendae et tonsurae petrae in formatione, ut aptare possit ad formationem mollem, medium et duram.Conus frenum dividi potest in molas (ferro dentium) frenum, et tcI conus momordit secundum genus dentium.

Characteres

Secundum materiam secantis, dividi potest in dentem chalybem (dente mola) et carbide inserere carbide (TCI) dente cylindro pyramis manditam.

In Tricone frena TCI terebratio mediae ad petram duram formandam.

Mediae formatio TCI triconis notae calcariae infestantibus carbide tungsten in calcaneum ordines et ordines interiores insertas.

Hoc consilium celeritatem exercendorum ratem praebet et structuram secans durabilitatem in medio ad medias formas duras addit.In HSN Flexilis O-anulus signationem idoneam praebet ad vetustatem ferendam.

Formatio dura TCI triconis frena adhiberi potest ad formationem duram et abrasivam exercitio.Gerunt resistentia tungsten carbide insertas adhibentur in ordinibus exterioribus ad impediendam METIOR frenum.Maximum numerum insertorum hemisphaericum conformatorum in omnibus ordinibus adhibentur ad vetustatem dromonis et longam vitam.

Tricone frena Structure

Ductu Tricone Bit Choice

| IADC | WOB(KN/mm) | RPM(r/min) | RECTUS FORMATIONIS |

| 114/116/117 | 0.3~0.75 | 180~60 | Formationes mollissimae cum pressivis vi et magna exercitibilitate humilium, ut argillae, mudstone, creta, etc. |

| 124/126/127 | 0.3~0.85 | 180~60 | Formationes molles cum vi compressivae et altae exercitationis, ut mudstone, gypso, sal, calcis mollis, etc. |

| 134/135/136/137 | 0.3~0.95 | 150~60 | Mollis ad medias formas cum vi compressiva et magna exercitio, ut media mollis shale, gypsum durum, calcis media mollis, sabuleum molle medium, formatio mollis cum duriore interjecta, etc. |

| 214/215/216/217 | 0.35~0.95 | 150~60 | Mediae formationes cum viribus altis compressis, ut media mollis sativa, gypsum durum, calcis media mollis, sabuleum molle medium, formatio mollis cum duriore interbeda, etc. |

| 227 | 0.35~0.95 | 150~50 | Medii formationes durae cum magnis compressivis viribus, ut abrasive shale, calcis, tonsae, dolomite, gypsum, marmor, etc. |

| Nota: limites superiores WOB et RPM in mensa superna simul non debent adhiberi. | |||

De ductu triconis Bits ChoiceTricone Bits Tooth Type

Bits Size

| Bit Size | API REG PIN | Torque | Pondus | |

| Inch | mm | Inch | KN.M | Kgs |

| 3 3/8 | 85.7 | 2 3/8 | 4.1-4.7 | 4.0-6.0 |

| 3 1/2 | 88.9 | 4.2-6.2 | ||

| 3 7/8 | 98.4 | 4.8-6.8 | ||

| 4 1/4 | 108 | 5.0-7.5 | ||

| 4 1/2 | 114.3 | 5.4-8.0 | ||

| 4 5/8 | 117.5 | 2 7/8 | 6.1-7.5 | 7.5-8.0 |

| 4 3/4 | 120.7 | 7.5-8.0 | ||

| 5 1/8 | 130.2 | 3 1/2 | 9.5-12.2 | 10.3-11.5 |

| 5 1/4 | 133.4 | 10.7-12.0 | ||

| 5 5/8 | 142.9 | 12.6-13.5 | ||

| 5 7/8 | 149.2 | 13.2-13.5 | ||

| 6 | 152.4 | 13.6-14.5 | ||

| 6 1/8 | 155.6 | 14.0-15.0 | ||

| 6 1/4 | 158.8 | 14.4-18.0 | ||

| 6 1/2 | 165.1 | 14.5-20.0 | ||

| 6 3/4 | 171.5 | 20.0-22.0 | ||

| 7 1/2 | 190.5 | 4 1/2 | 16.3-21.7 | 28.0-32.0 |

| 7 5/8 | 193.7 | 32.3-34.0 | ||

| 7 7/8 | 200 | 33.2-35.0 | ||

| 8 3/8 | 212.7 | 38.5-41.5 | ||

| 8 1/2 | 215.9 | 39.0-42.0 | ||

| 8 5/8 | 2191 | 40.5-42.5 | ||

| 8 3/4 | 222.3 | 40.8-43.0 | ||

| 9 1/2 | 241.3 | 6 5/8 | 38-43.4 | 61.5-64.0 |

| 9 5/8 | 244.5 | 61.8-65.0 | ||

| 9 7/8 | 250.8 | 62.0-67.0 | ||

| 10 | 254 | 68.0-75.0 | ||

| 10 1/2 | 266.7 | 72.0-80.0 | ||

| 10 5/8 | 269.9 | 72.0-80.0 | ||

| 11 1/2 | 292.1 | 79.0-90.0 | ||

| 11 5/8 | 295.3 | 79.0-90.0 | ||

| 12 1/4 | 311.2 | 95.0-102. | ||

| 12 3/8 | 314.3 | 95.0-102.2 | ||

| 12 1/2 | 317.5 | 96.0-103.0 | ||

| 13 1/2 | 342.9 | 105.0-134.0 | ||

| 13 5/8 | 346.1 | 108.0-137.0 | ||

| 14 3/4 | 374.7 | 7 5/8 | 46.1-54.2 | 140.0-160.0 |

| 15 | 381 | 145.0-165.0 | ||

| 15 1/2 | 393.7 | 160.0-180.0 | ||

| 16 | 406.4 | 2000-220.0 | ||

| 17a | 444.5 | 260.0-280.0 | ||

| 26 | 660.4 | 725.0-780.0 | ||

Processus productionis

| Minimum Quantitas Ordinis | N/A |

| Pretium | |

| Packaging Details | Latin Export Delivery Package |

| Tempus adferendi | 7days |

| Pensio conditio | T/T |

| Facultates copia | Ex Ordine Detailed |